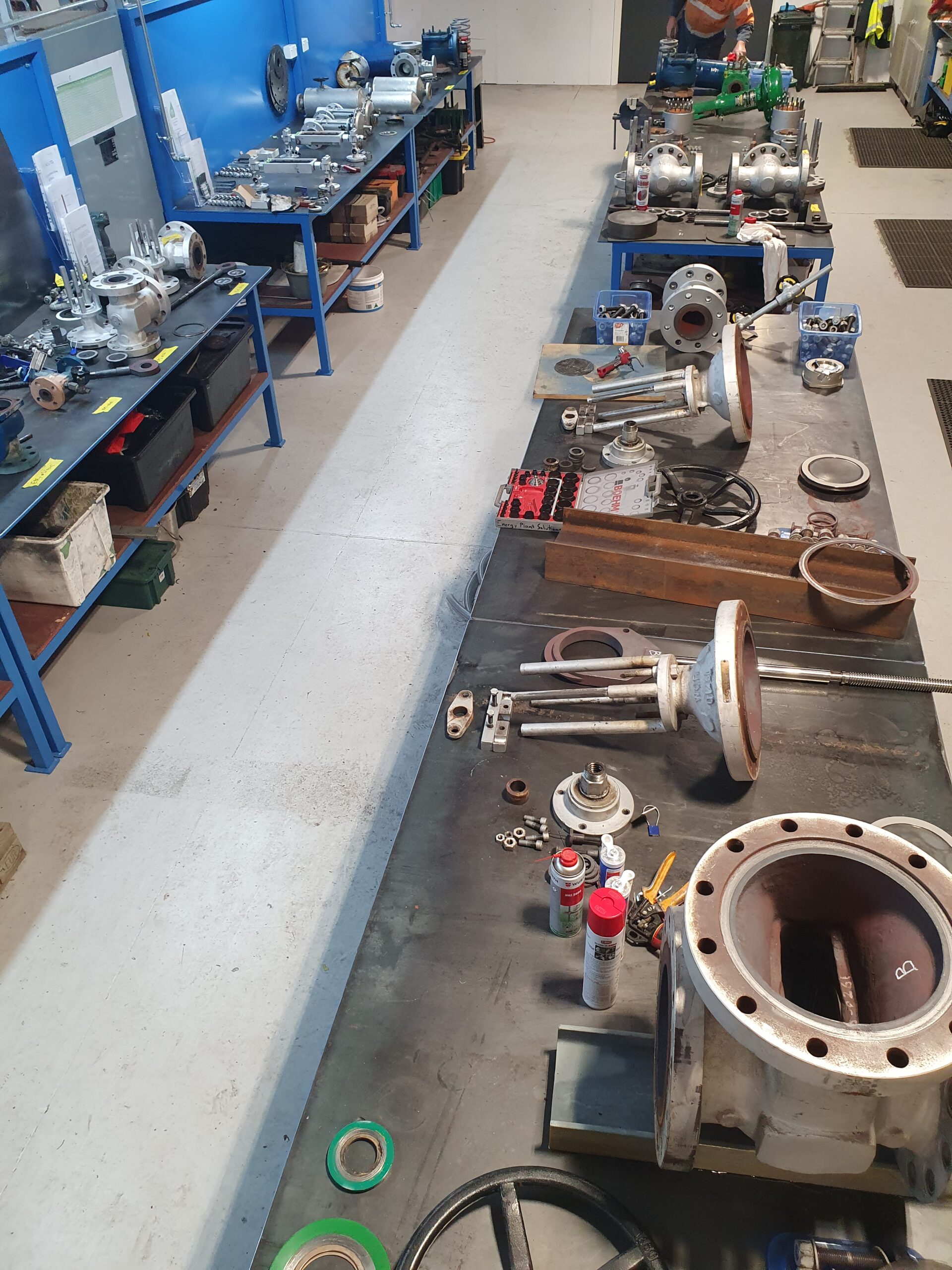

Valve Servicing

Energy Plant Solutions specialise in valve reconditioning and servicing. We have designed and manufactured specialised equipment, allowing us to repair a wide range of valving, including isolation valves, control valves, blow down valves, level gauges, stop checks and safety valves.

We pride ourselves on our extremely high quality of workmanship and our ISO 9001 approved systems. In many cases with older valving, replacement parts are not available. Energy Plant Solutions can manufacture a large variety of new replacement components, allowing such expensive valving to be utilised for many years to come, thus reducing our client’s operating costs, and ensuring they can rely on the valves that we have reconditioned. Before dispatch from our facility, valves are nitrogen pressure tested on our calibrated test rig in our climate controlled testing facility, or on site on our portable test rig. An identification tag is attached to the valves with a locking device which, in the case of certified valves, is fitted in such a way as to inhibit any adjustment of the pressure relief setting. Each valve has its own test report that is identified by the unique valve identification number. We have many satisfied customers who rely on our proven ability to offer superior quality in this field throughout New Zealand.

Energy Plant Solutions also specialise in reconditioning steam and compressed air soot blowers. If required, we have the ability to ‘line bore’ your damaged soot blower housings oversize, and in turn manufacture new oversized pistons complete with new piston rings to suit, thus turning your damaged unit into an ‘as new’ functioning soot blower. This is often a very cost effective repair when compared to the expensive alternative of a replacement unit. In addition, we also manufacture new lances should your units be damaged due to overheating or wear from steam during long periods of service.